For the last year and a half, I have been working on a cantilevered working desk that can be used to work comfortably from any chair or sofa. I have built about 8 prototypes which are chronicled here.

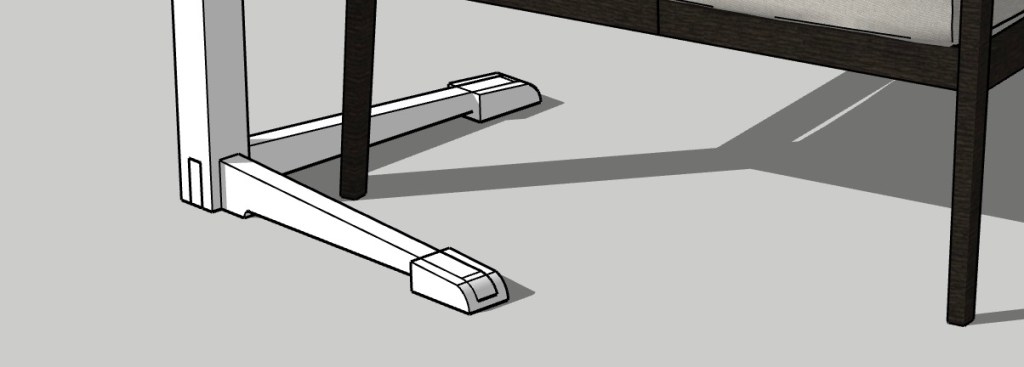

The form has evolved to meet three simple requirements. It needed to be lightweight, sturdy and portable. I insisted on a cantilevered top to offer a large work space and efficient base that fits under and around chair legs.

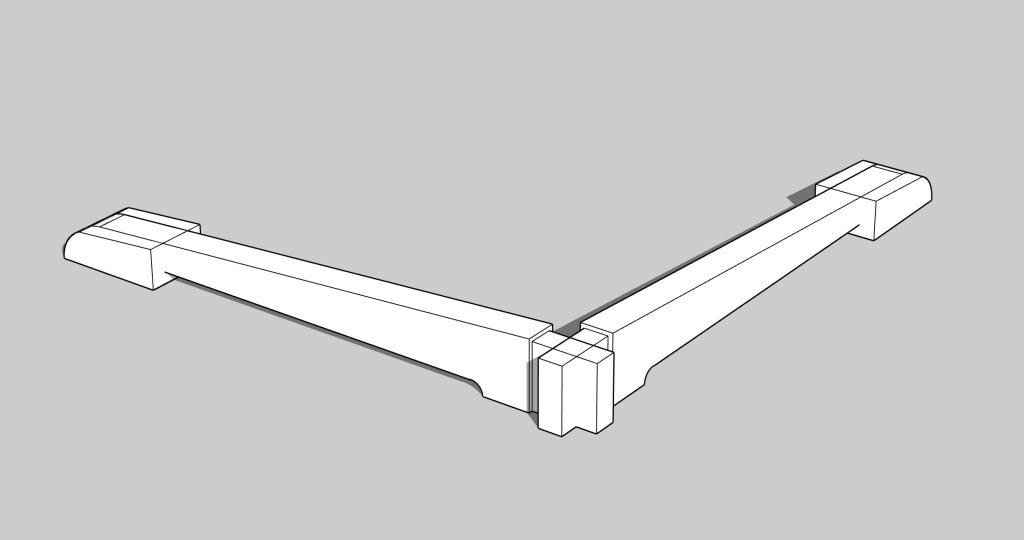

The first idea involved a large box joint to create a corner and formed the base. This was lightweight but looked flimsy. I then started using a castle joint. It is an ideal solution that does not feel over-engineered.

In the version 6 prototype, I found the right thickness of the legs and feet (42mm), and then also solved how to integrate correct size base with the top. It create a simple profile. This is elegant, minimal but comfortable. I am not a minimalist as I find it uncomfortable, but in this case it is well suited.

The cantilevered form solves many problems in small spaces as its foot print is less demanding. So I see extending this into an entry console and compact writing desk. I will also explore this form as a drop table.

With this project, I also see cleaver ways to keep costs down for custom furniture. The materials for this piece can be cut offs with nothing over 24 inches long required. I expect as I perfect the process of cutting castle joints, this piece can be made quickly out of quality hardwood. I want to make accessible custom furniture. Anyone can make a side table for $500.