I did finish the updated work table and delivered it. Then got an email that one of feet failed.

When I investigated, the table was used with a fairly heaving rocking lounge chair. When the chair frame tipped forward, it applied a racking force to the foot. Racking force is when a joint is pushed laterally from the side, rather than straight down. The leg failed along the vertical grain just after the mortise. This highlighted a couple design issues:

- Table was not designed to be used with a rocker, but that is what happened. I design for real use.

- The height of the foot was enough create a lever that created the racking force.

- The floating mortise joint did not fail.

The table was easily repaired but the flaw still remains.

New Design Needed

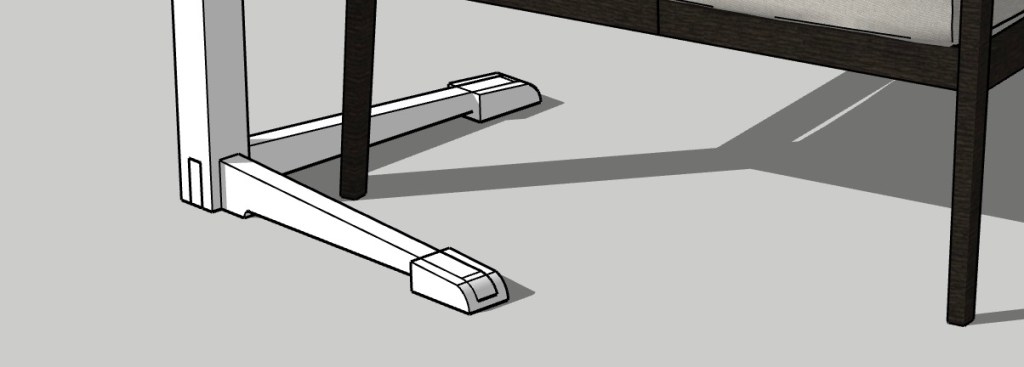

This table needs to be portable and sturdy so it can be pulled in close to chairs and sofas. The issue with the failed design is in the decision to have the leg “flow” into the foot using a curve.

It does not seem possible to curve the leg into foot and cantilever the top. The curve is not needed to deliver on the design brief.

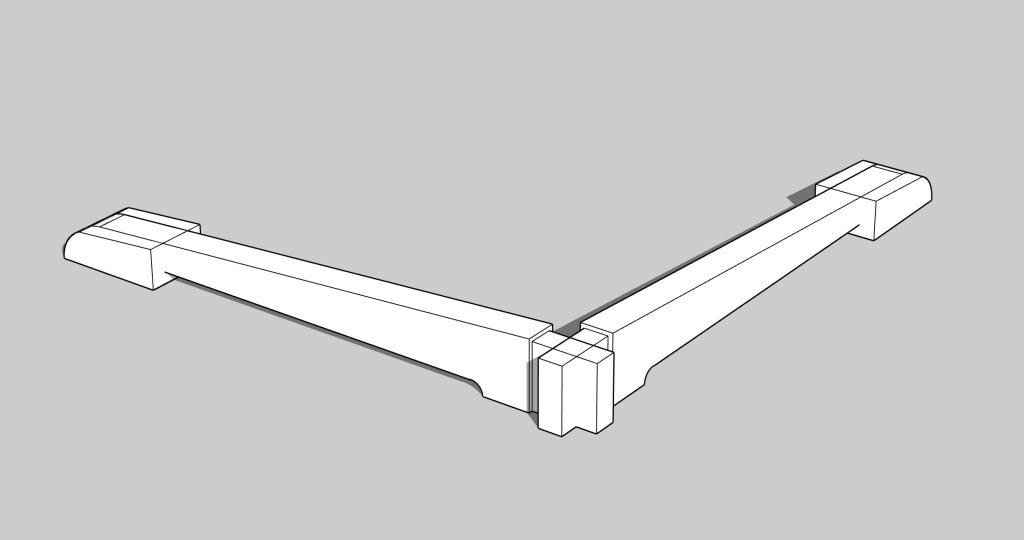

I reviewed my sketches and decided on featuring a castle joint. The joint interlocks of all three pieces of wood making up the leg and both feet. The 2 feet are joined with a half-lap joint and this assembly then fits into slots into a thicker leg.

This design eliminates the non-traditional box joint for the leg and replaces it with more traditional joint.

The cantilevered top and corner leg frame allow the user to pull the table surface in close. The added “toes” should allow it to slide under furniture with more durability. I hope it will also allow it to be used on thicker carpeting.